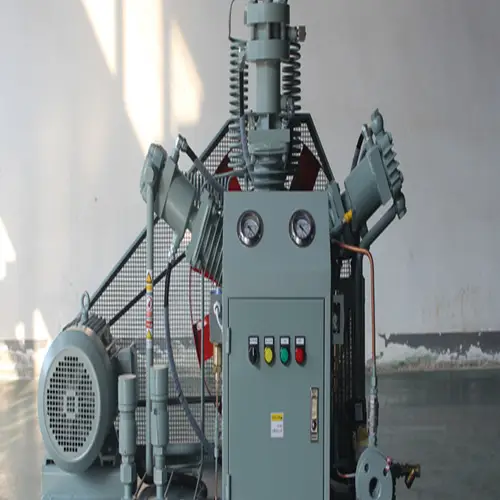

China Good quality High Pressure CO2 Compressor Popular Model air compressor lowes

The China Good quality High Pressure CO2 Compressor Popular Model is a reliable and top-quality compressor designed for compressing medium and high-pressure gases. Manufactured according to national standards, it is specially designed for medical oxygen gas compressing and oxygen cylinder filling purposes. This compressor is completely oil-free, ensuring no oil contamination in the compressed gas, making it a safe and reliable choice for customers.

The High Pressure CO2 Compressor is constructed with stainless steel parts that come into contact with the gas, guaranteeing long-term stability and service. Its excellent features include simple control, automatic working system, no leakage, and convenient maintenance. With a compact size and lightweight design, it is easy to operate and move.

Product Specifications

| No. | Item | Data |

| 1 | Compressor model | GOW-30/4-150 |

| 2 | Compressor type | V type, reciprocating piston, water cooled, air cooled |

| 3 | Compression medium | oxygen |

| 4 | Volume flow | 30nm3/h |

| 5 | Intake pressure | 4bar |

| 6 | Exhaust pressure | 150bar |

| 7 | Inlet temperature | ≤40ºC |

| 8 | Exhaust temperature | no more than ambient temperature +15ºC after cooling |

| 9 | Driving mode | explosion-proof motor |

| 10 | External size (length × width × height) | 1650*950*1470mm |

| 11 | Weight | 960kg |

Product Advantage

| 1 | Totally 100% oil-free type High Pressure CO2 Compressor, ensuring no oil content in the cylinder. |

| 2 | Suitable for compressing various gases like Oxygen, Hydrogen, Nitrogen, Helium, Argon, CO2, Air, Biogas, Methane, and other special gases. |

| 3 | No pollution, maintaining the same purity level as the inlet gas. |

| 4 | Reliable and top quality, comparable to renowned brands like RIX. |

| 5 | Outstanding cost performance, low maintenance cost, and easy operation, with piston ring replacement being the only requirement. |

| 6 | Piston ring working life of up to 4000 hours, with the final stage ring lasting 1500-2000 hours. |

| 7 | Equipped with top brand motors, like CHINAMFG, ensuring high-quality performance. |

| 8 | Approved for quality standards such as CE, ISO9001, and ISO13485. |

| 9 | The compressor is designed for various pressure ranges, from 2MPa to 30MPa, meeting different application needs. |

| 10 | The device has a small size, lightweight, easy maintenance, and is suitable for filling high-pressure air displacement and small to medium-sized gas stations. |

Product Application

The High Pressure CO2 Compressor is widely used in industries requiring compressed gases, including medical facilities, gas stations, and industrial applications. It is suitable for compressing gases like Oxygen, Hydrogen, Nitrogen, Helium, Argon, CO2, Air, Biogas, Methane, and other special gases.

For more information about our products, please visit our website or contact our sales team.

EVER-POWER GROUP mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. We are committed to providing high-quality products, competitive prices, and excellent customer service. Customization of drawings and samples is welcomed.

Frequently Asked Questions (FAQs)

1. Can this High Pressure CO2 Compressor be used for medical oxygen gas compression?

Yes, the High Pressure CO2 Compressor is specifically designed for medical oxygen gas compressing and oxygen cylinder filling purposes.

2. Is the compressor completely oil-free?

Yes, the High Pressure CO2 Compressor is 100% oil-free, ensuring no oil contamination in the compressed gas.

3. What materials are used in the construction of this compressor?

All parts that come into contact with the gas are made of stainless steel, ensuring long-term stability and service.

4. What are the advantages of this compressor compared to other brands?

This compressor offers reliability, top quality, and cost-effective performance comparable to renowned brands. It also requires low maintenance and has a long working life for piston rings.

5. Which industries can benefit from this High Pressure CO2 Compressor?

The High Pressure CO2 Compressor is suitable for various industries, including medical facilities, gas stations, and industrial applications, where compressed gases like Oxygen, Hydrogen, Nitrogen, and other special gases are required.

All the content of this page is from the Internet. The content is only as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of CO2 Compressors

Energy Efficiency

CO2 compressors are known for their high energy efficiency. Due to their advanced technology and design, they are able to compress CO2 gas with minimal energy consumption. This not only helps in reducing operational costs but also contributes to a greener and more sustainable environment.

Low Noise Levels

One of the key advantages of CO2 compressors is their low noise levels during operation. They are designed to minimize noise pollution, making them suitable for various applications where noise reduction is essential. This feature ensures a quieter and more comfortable working environment.

Compact Design

CO2 compressors are designed to be compact and space-saving. Their small footprint allows for easy installation even in areas with limited space. This makes them ideal for industries where space optimization is crucial.

High Reliability

CO2 compressors are known for their high reliability and durability. They are built with robust materials and undergo rigorous quality control measures to ensure consistent performance even in demanding conditions. This reliability ensures minimal downtime and maximum productivity.

Types and Characteristics of CO2 Compressors

Reciprocating Compressors

Reciprocating CO2 compressors are widely used for their high efficiency and reliability. They operate by using pistons to compress the CO2 gas. These compressors are known for their ability to handle high-pressure applications and are commonly used in industries such as oil and gas.

Screw Compressors

Screw CO2 compressors are known for their continuous and smooth operation. They use rotating screws to compress the CO2 gas, resulting in a steady flow of compressed gas. These compressors are commonly used in applications that require a constant and stable supply of compressed CO2.

Centrifugal Compressors

Centrifugal CO2 compressors are characterized by their high flow rates and low maintenance requirements. They use centrifugal force to compress the CO2 gas, making them suitable for applications that require large volumes of compressed gas, such as in the beverage industry.

Advantages of CO2 Compressors Made of Different Materials

Stainless Steel

CO2 compressors made of stainless steel offer excellent corrosion resistance, making them suitable for applications in harsh environments. They are highly durable and require minimal maintenance, ensuring long-term performance and reliability.

Aluminum

CO2 compressors made of aluminum are lightweight and offer good heat dissipation properties. They are commonly used in portable applications where weight and thermal management are important factors. Aluminum compressors are also cost-effective and can be easily replaced if necessary.

Cast Iron

CO2 compressors made of cast iron are known for their strength and durability. They can withstand high pressures and are ideal for applications that require heavy-duty performance. These compressors are commonly used in industries such as oil and gas, where reliability and longevity are crucial.

Application of CO2 Compressors

Beverage Industry

CO2 compressors play a vital role in the beverage industry, where they are used for carbonation and pressurization processes. They ensure the consistent quality and taste of carbonated beverages while maintaining high production efficiency.

Food Processing

In the food processing industry, CO2 compressors are used for various applications such as cooling, freezing, and packaging. They help in maintaining the freshness and quality of food products while ensuring efficient and hygienic processing operations.

Greenhouses and Agriculture

CO2 compressors are essential in greenhouse operations as they provide the necessary CO2 for plant growth. They help enhance photosynthesis, resulting in improved crop yields and quality. Additionally, CO2 compressors are used in agricultural applications for soil aeration and pest control.

Dry Ice Production

CO2 compressors are widely used in the production of dry ice, which is used for various purposes such as cooling, cleaning, and transportation of perishable goods. These compressors ensure efficient and reliable production of high-quality dry ice.

Oil and Gas Industry

The oil and gas industry relies on CO2 compressors for several processes, including gas injection, enhanced oil recovery, and gas separation. CO2 compressors play a crucial role in maintaining optimal pressure levels and ensuring efficient operations in this industry.

Future Development Trends and Opportunities

The future of CO2 compressors looks promising, with several trends and opportunities emerging in the industry. One of the key trends is the growing demand for environmentally friendly solutions, which drives the adoption of CO2 compressors due to their low carbon footprint and energy efficiency.

Another trend is the increasing focus on renewable energy sources, such as biogas and hydrogen production, where CO2 compressors play a vital role in the compression and purification processes. This presents opportunities for further advancements and innovations in CO2 compressor technology.

Furthermore, the expanding applications of CO2 compressors in emerging industries like carbon capture and storage, as well as the continuous development of CO2-based refrigeration systems, offer significant growth potential for the industry.

How to Choose a Suitable CO2 Compressor

When selecting a suitable CO2 compressor, several factors should be considered:

Clear Requirements

Define your specific requirements, including the desired flow rate, pressure range, and any other relevant parameters. This will help in identifying the most suitable compressor for your needs.

Material Selection

Consider the material of the compressor based on the intended application and environmental conditions. Different materials offer varying levels of durability, corrosion resistance, and heat dissipation properties.

Design Optimization

Look for compressors with optimized designs that enhance efficiency and reliability. Features such as advanced cooling systems, noise reduction technology, and intelligent control systems can significantly improve performance.

Suppliers and After-sales Service

Choose a reliable supplier who can provide quality products and excellent after-sales service. Ensure that they offer warranty coverage, spare parts availability, and technical support when needed.

Cost-effectiveness

Evaluate the overall cost-effectiveness of the compressor, considering factors such as initial investment, energy consumption, and maintenance costs. A thorough cost analysis will help in making an informed decision.

Quality Control

Check the supplier’s quality control processes to ensure that the compressor meets industry standards and regulations. This will help in avoiding potential performance issues and ensuring long-term reliability.

Author: Dream